The challenges of being a fire-fighter – a personal account

“Frustration comes with knowing you need to perform a rescue operation, but you don’t have the correct PPE.” Emile Conrad shares the challenges of his job as a fire-fighter in George, Western Cape. “Most of the fires we fight are in the wild; veld, forest and mountain, and this means the terrain is treacherous and the conditions are unforgiving, so we rely heavily on our gear to keep us safe.”

Emile never imagined his life’s journey would lead him to fire-fighting, in fact, he had his heart set on carpentry, something which he has a natural talent for. “I grew up and went to school in Atlantis; and I saw myself pursuing woodwork and carpentry as a career.” It was only when South Africa went into recession that Emile was forced to seek an alternative means of income. “My then girlfriend, who is now my wife, worked in the fire services for the City of Cape Town. It was actually one of her colleagues who pushed me to do a fire-fighting course”.

After several attempts to gain employment with the fire services in Cape Town, Emile finally signed a 2-year contract with the Garden Route District Municipality as a fire-fighter and left for George in 2009, and “never looked back”.

George is one of the country’s hardest hit areas when it comes to wildland and bush fires, and fires can rage seemingly unabated for days. When Emile is questioned about what goes through his head when he is thrust into a life or death situation, he chuckles, “You have to know when to push and when to pull back. Strength of mind plays a huge role; of course, this is a very physically demanding job but your mind is your strongest weapon because fear can paralyse you.” Emile’s strength of mind is supported by his lifestyle. As an avid CrossFit athlete, Emile dedicates time off-duty to his fitness and strength training. Fire fighters are normally on duty for 12 hours at a time, and if not out on a rescue, Emile likes to spend his time pushing his limits, “After I won the Toughest Fire Fighter Competition in the Western Cape in 2011, the bug had bitten. The competition went national in 2012, and I placed second – that was a hard pill to swallow and I knew that if I was going to be the best, I had to get serious about my training. I now have my own training rig at home, and when I’m on off-duty, I don my structural firefighting gear with my backpack and do a few circuits.”

Emile went on to win the nationals in 2013, 2014, 2016, 2018 and 2019, an accolade which bears testament to his rigorous training regime and single-minded approach. He knows that good PPE also gives him the edge, “Wearing my Charnaud fire suit gives me the opportunity to simulate real life rescue situations during my training. A fire suit can weigh between 4 to 6 kilograms depending on the design and the manufacturer, with some suits having one up their competitors when it comes to crucial aspects like breathability and flexibility and this makes a big difference in terms of the time it takes to perform a rescue.”

In 2016 CHARNAUD® came on board to personally sponsor Emile with his own custom-fitted CHARNAUD® FIRE-SAFE® AIR-LITE Bunker Suit. Keen to educate Emile about what sets the CHARNAUD® AIR-LITE Bunker Suit apart, he was invited to tour their factory in KwaZulu-Natal, to see the manufacturing process first-hand and to have his bunker suit custom fitted.

Aside from direct heat exposure, heat stress is a very real challenge for fire fighters as heat builds up inside the suit. The difference between a good and an industry-leading fire suit is its interior membrane. The interior membrane is what enhances the suits ability to disperse heat better, a vital component in this line of work. Emile gives a glimpse into what it is like wearing a fire suit in a structural rescue. “It gets very hot inside your suit. Even if you’ve done it a hundred times, the discomfort never goes away. This is where a strong mind helps, because you know you have to put your discomfort aside for the good of others and in order to perform a rescue. But some suits are better than others; and having had the opportunity to wear the CHARNAUD® AIR-LITE® bunker suit for the last 5 years, has made me realise that the alternative PPE we use doesn’t always meet the same standards.” He continues, “I’m privileged to be able to have CHARNAUD® sponsor me, and now that I’ve had the chance to wear a different kind of suit I can say that the CHARNAUD® suits definitely gives me more – its heat dispersion is better, it’s a lighter suit and its way more flexible. Flexibility in a fire suit is as important as breathability because limited suit flexibility coupled with high heat can cause you to fatigue sooner.”

When asked whether he ever dreams about doing something else with his life, Emile replies, “This is my calling, I realise that now. My wife was in fire services before me, but I never thought I’d end up here. The nature of my job is unpredictable you never know what you’re going to face and that keeps me mentally alert and forces me to stay physically fit; you can say it really tests my limits and exposes my weaknesses. Fear is always there but I lean on my faith, the years of on-the-job experience and having the correct lifesaving PPE to enable me to save lives”.

“We are always talking about how to perform a rescue better and quicker and its true when I say that taking those few extra seconds to put the right PPE on ultimately saves you minutes. The old saying is ‘Training saves seconds, seconds save minutes and minutes save lives’, so wear your PPE.” He ends by explaining how world-class PPE has helped him to claim first place in the SAESI (South African Emergency Services Institute) Combat Challenge in 2017, “This competition is described as the toughest 2 minutes in sport, and I managed to shave 20 seconds off my previous time and to win first place. My CHARNAUD® AIR-LITE® bunker suit definitely contributed to my success.”

www.charnaud.net

- Published in Uncategorized

Holmatro extends Pentheon series with twelve new rescue tools

Following the launch of the Pentheon Series in May 2020, Holmatro now introduces twelve additional cordless rescue tools to complete the range.

Like the first four tools in this series, the new models offer unparalleled speed, ultimate control and extremely easy battery management. The Pentheon Series is designed to outperform all other rescue tools on the market, regardless of whether these are battery-powered or connected to an external pump by means of a hose.

The complete Pentheon Series

In addition to Cutter PCU50, Spreader PSP40, Combi Tool PCT50 and Telescopic Ram PTR50 the Pentheon Series now includes the following new rescue tool models:

Whether you are looking for compact and lightweight models for rapid interventions or larger models for heavy-duty applications, the extended Pentheon Series can meet any rescue tool requirement.

Pentheon features and benefits

The twelve newly added tools have the same features & benefits as the four existing models. Some important ones are:

• Stepless Speed Maximization. Patented technology maximizing speed at any tool load. Where other battery tools show a significant drop in speed when switching to another stage to deal with the higher loads, Pentheon tools stick to the ideal speed curve.

• Two-Mode Control Handle for ultimate tool control. This enables you, at any time during the rescue operation, to choose between the tools’ high-speed and low-speed modes. Simply turn the control handle further to its left or right to switch between both modes.

• On-Tool Charging: Battery management made easy. Leave the battery to charge on the tool. Simply plug the tool into the charger and the whole charging process will regulate itself. The battery on the tool always has priority over the one on the charger. The maximum configuration that can be powered from one outlet consists of three tools, three chargers and six batteries.

• Extended working time. This is thanks to a purpose-built battery with increased capacity, an energy efficient drive system and an Auto Start/Stop system. In addition, Temperature Management Technology allows you to keep working with Pentheon tools in extremely hot conditions.

• Under water use. Pentheon tools can be used while being fully submerged in water. Batteries can be swapped under water too.

• Smart Ram Extension. When using one of the optional extension pipes (440mm/17.3in and 220mm/8.7in) the ram automatically adapts its force to the new maximum length that can be achieved. Quick and simple connection of the extension pipes over the ram head.

• Realtime diagnostics. LED indicators on the tools, batteries and chargers provide real-time feedback on tool temperature, max. pressure reached, battery temperature, battery state of charge and battery state of health.Immediately visible, no need to press a button first. More information can be obtained with the help of free Holmatro Diagnostics Software.

• Compact and inline tool design. This is achieved through a patented integrated motor & pump sharing the same shaft and a battery that fits around the tool like a bracelet.

For more information, please go to

www.holmatro.com/pentheon.

Technical specifications of all Pentheon Series rescue tools can be found in the product catalog on the Holmatro website.

- Published in Uncategorized

Are you in the emergency services or education sectors?

There is still time to register

It is time to take training to another level with virtual reality and SkillsTrain. Virtual Reality Training is the digital simulation of lifelike scenarios for training purposes and in this webinar, we will be taking you through the FLAIM Extinguisher and practically show you HOW it immerses trainees in virtual reality, delivering a realistic simulation of a range of fire events to efficiently train first responders. For further information contact: 082 552 7742 or Click here to register for this FREE event hosted by an awesome line-up of international speakers: https://zoom.us/webinar/register/8816256481845/WN_l_lhYyBAR_u-Ka3oggmcsg=

- Published in Uncategorized

Are you in the emergency services or education sectors?

There is still time to register

It is time to take training to another level with virtual reality and SkillsTrain.

Virtual Reality Training is the digital simulation of lifelike scenarios for training purposes and in this webinar, we will be taking you through the FLAIM Extinguisher and practically show you HOW it immerses trainees in virtual reality, delivering a realistic simulation of a range of fire events to efficiently train first responders.

Click here to register for this FREE event, hosted by an awesome line-up of international speakers:

- Published in Uncategorized

EMS Guide – Volume 30

Time doesn’t stand still for anyone or anything, not even for our EMS Guide which turns 30 this year.

Although the Covid pandemic has been a disaster for many companies, it has also made many look at new possibilities or better ways to conduct business.

Before Covid-19, magazine publishing was already turning to digital as its leading platform, we were however still stuck on the printed book as our main means of distribution. With the postal system becoming unreliable over the past few years, and delivery times coming to almost a standstill during Covid, we decided to focus on a larger digital presence. We never anticipated how successful it would be, nor the positive spin-offs that would come out of it. Instead of posting hundreds of Buyer’s Guides and then losing track of them, we can now see how many people are reading and using the book, we can keep track on our subscribers, how many countries we reach and which ones, we can see how many new and repeat users we have – all this on a daily basis.

Our newsletters – the new feature we introduced last year – are delivered directly to the inbox of our subscribers and remain forever on our website as a reference. They are individualised so that only one company has the entire platform to themselves at a time, keeping the end-user up-to-date on new products on the market and any relevant company changes.

We are now busy with our volume 30. Please email us at delinds@mweb.co.za if:

1. You want to advertise

2. Want to get a hard copy over and above the digital copy

3. Any emergency services department or suppliers wanting to update their information.

We would also appreciate feedback on the changes we made this year – good or bad, and any suggestions for improving our service and Buyer’s Guide.

- Published in Uncategorized

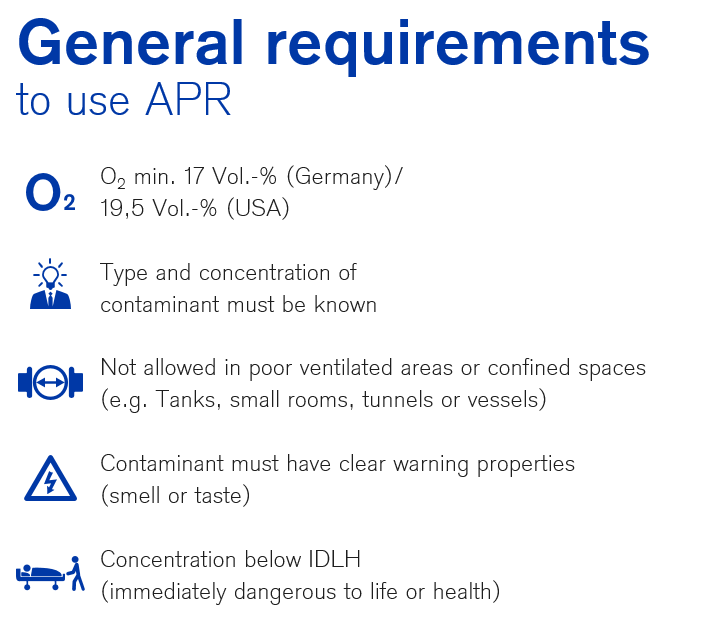

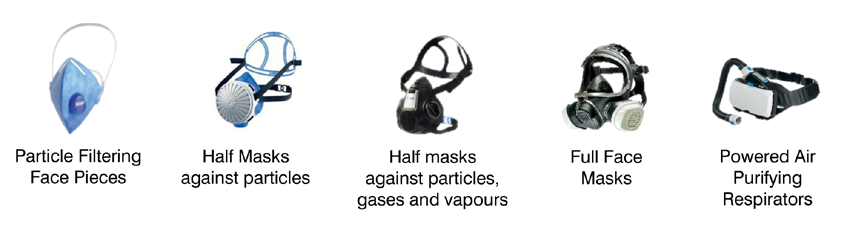

Choosing the right respiratory device

+

When it comes to selecting the right respiratory protection there are some important factors to consider: Knowledge of the existing contaminants, application requirements, respirator limitations and the protection levels each offers. Sound complicated? You are not alone, Dräger has the right tools to support you and will help you every step of the way.

Lets look at the approvals of the systems mentioned above:

Daily use

All over the world, many different standards and approvals

Our experts take these regulations into account during the whole lifecycle.

Each filter is CE-certified in accordance with the valid version of EN 14387, EN 143:2000 or the DIN 58620 for CO filters.

Further local approvals are available for some of our X-plore filters, e.g. EAC (Russia), LA (China), NBR (Brazil), SANS (South Africa)

EN 14387. Standard for gas and combination filters

EN 143. Standard for particle filters

DIN 58620. Standard for CO filters

AS/NZS 1716. Australian standard

Filtered escape devices

Two main standards are applicable for the PARAT escape hood series:

DIN 58647-7 for filtering escape devices and EN 403:2004 for fire escape hoods.

In addition, the filters of the PARAT 4700 and 7500 are tested in accordance with EN 14387:2004.

The filter of the PARAT 5500 fire escape hood is additionally tested for the use against H2S (at 2,500 ppm) in accordance with DIN 58647-7.

Air purifying respiratory protection

X-plore filters can be used with half masks X-plore 3000 or with full-face masks X-plore 5500 and X-plore 6000.

In addition, Rd40 filters can be used with any half and full-face mask with a standard filter connection. Dräger also offers disposable particle filtering face pieces and even powered air purifying respirators.

Applications for the X-plore Filters

Equipment for fast and safe escape

Emergencies need an expert:

Unplanned situations with hazardous substances can occur within seconds. No escape scenario is the same.

Individual situations need individual escape concepts fitting to your company’s environment.

Applications for the Parat filtered escape devices

Day to day use

The broad portfolio of X-plore filters offers high protection against almost every hazardous substance, including CO* and radioactive methyl iodide*. In total more than 70 different filters are available.

Effective protection against hazardous substances when working with wood, Laboratory work, Painting and Welding as examples. You have to protect your respiratory organs against a diverse range of gases.

*Only Rd40 filter series

Filtered Escape devices

When every second counts, ready for escape in only 3 steps. This saves valuable seconds in emergencies; during maintenance operations, for fire fighters in case of fire to rescue people from the affected area, protection against carbon monoxide during operational use and when fire related and industrial gases might be present at the same time.

Follow the links below for more information on our X-Plore filers and our Parat escape devices;

Day to day Use: https://www.draeger.com/en_za/Safety/Respiratory-Protective-Equipment

Escape and rescue: https://www.draeger.com/en_za/Productselector/Rescue-and-Escape?page=1&i=safety

- Published in Uncategorized

Burnt alive!

Why are workers still being killed in factory fires in Bangladesh?

It is hard to believe that employers and factory owners in Bangladesh still lock fire doors and prevent workers from escaping in the event of a fire.

Eight years ago in 2013, I wrote a damming article about the criminal activities of Bangladesh employers, and the government.

Why is it that eight years later I am asking “How long will it be until factories in Bangladesh manufacturing goods for Canada, the U.S. and European-headquartered companies are safe for workers? Why am I writing about another 52 workers who died in another factory fire in Bangladesh on July 8th, 2021? How can it be in this day and age factory owners are still locking doors preventing workers from escaping fire?

At the Hashem Food and Beverage factory in Rupganj, an industrial town 15 miles east of Dhaka, 52 workers, including children as young as 11, died in a massive fire that began on July 8 and raged on for more than a day, according to a report from Al Jazeera.

The news outlet reported that Jayedul Alam, police chief for Narayanganj district where the factory is located, said the entrance had been padlocked at the time of the blaze and the factory breached multiple fire and safety regulations. A fire services spokesman also said the exit door to the main staircase had been padlocked. Highly flammable chemicals and plastics had also been stored in the building.

If this sounds all too familiar, Bangladesh, which employs tens of thousands of low-paid workers making garments for large international companies has a long and tragic history of industrial disasters.

Continuing corruption and a lack of enforcement have resulted in hundreds of deaths over the years. It is widely believed that the only way to prevent these criminal acts is to boycott clothing produced in Bangladesh.

After the horrific collapse of the Rana Plaza garment factory during 2013 that killed more than 1,100 people, the country imposed tougher safety rules. An agreement between Bangladeshi unions and international brands was signed – The Accord on Fire and Building Safety in Bangladesh. It was a five-year agreement signed in May 2013 and extended until 2018. The next expiry date is August 31, 2021.

According to Remake, the initial inspection of Bangladesh’s factories in 2013 found “more than 87,000 safety issues, including more than 50 factories that were at immediate risk of collapsing”. Since then, as a result of 38,000 initial and follow-up inspections, more than 90% of the original hazards which were identified have been eliminated.

While this is an important step, there are still issues. If there weren’t issues, we wouldn’t see headlines like these with regularity “the country’s garment industry has since become largely compliant under domestic and global watchdogs. But many other local industries fail to maintain safety compliance and the disasters have continued”.

In 2019, 67 people were killed when a complex housing warehouses, shops and apartments caught fire.

Responding to this latest tragedy the International Labor Association gave this statement:

“This incident illustrates the urgent need in Bangladesh for authorities and building owners to ensure that buildings in which thousands of workers spend the better part of their day are built and operated in compliance with national code requirements. If the fire safety measures required by the regulations were properly implemented, it would provide for the safe evacuation of occupants in this type of emergency”.

This cannot and should not ever happen again. Tighter regulations must ensure worker’s safety and we should never have to write another story like this.

When the people take back the power and hold public officials accountable, then and only then, will conditions change. In 1991, after the Imperial Chicken processing plant caught fire in Hamlet, North Carolina in which 25 people were killed, the owner did just under 4 years in prison because he had ordered the doors padlocked from the outside. It was not nearly enough, but it was the first time in North Carolina that someone did real prison time for safety violations.

This was a time of reckoning for NCs safety programmes. Laws were passed, people were held accountable. The feds threatened to take over North Carolina Labor unless certain minimum standards were implemented and John C. Brooks, Labor Commissioner at the time, lost the next election. Since 2004, North Carolina has been ranked in the top 5 safest states to work.

- Published in Uncategorized

Burnt Alive

Why are workers still being killed in factory fires in Bangladesh?

It is hard to believe that employers and factory owners in Bangladesh still lock fire doors and prevent workers from escaping in the event of a fire.

Eight years ago in 2013, I wrote a damming article about the criminal activities of Bangladesh employers, and the government.

Why is it that eight years later I am asking “How long will it be until factories in Bangladesh manufacturing goods for Canada, the U.S. and European-headquartered companies are safe for workers? Why am I writing about another 52 workers who died in another factory fire in Bangladesh on July 8th, 2021? How can it be in this day and age factory owners are still locking doors preventing workers from escaping fire?

At the Hashem Food and Beverage factory in Rupganj, an industrial town 15 miles east of Dhaka, 52 workers, including children as young as 11, died in a massive fire that began on July 8 and raged on for more than a day, according to a report from Al Jazeera.

The news outlet reported that Jayedul Alam, police chief for Narayanganj district where the factory is located, said the entrance had been padlocked at the time of the blaze and the factory breached multiple fire and safety regulations. A fire services spokesman also said the exit door to the main staircase had been padlocked. Highly flammable chemicals and plastics had also been stored in the building.

If this sounds all too familiar, Bangladesh, which employs tens of thousands of low-paid workers making garments for large international companies has a long and tragic history of industrial disasters.

Continuing corruption and a lack of enforcement have resulted in hundreds of deaths over the years. It is widely believed that the only way to prevent these criminal acts is to boycott clothing produced in Bangladesh.

After the horrific collapse of the Rana Plaza garment factory during 2013 that killed more than 1,100 people, the country imposed tougher safety rules. An agreement between Bangladeshi unions and international brands was signed – The Accord on Fire and Building Safety in Bangladesh. It was a five-year agreement signed in May 2013 and extended until 2018. The next expiry date is August 31, 2021.

According to Remake, the initial inspection of Bangladesh’s factories in 2013 found “more than 87,000 safety issues, including more than 50 factories that were at immediate risk of collapsing”. Since then, as a result of 38,000 initial and follow-up inspections, more than 90% of the original hazards which were identified have been eliminated.

While this is an important step, there are still issues. If there weren’t issues, we wouldn’t see headlines like these with regularity “the country’s garment industry has since become largely compliant under domestic and global watchdogs. But many other local industries fail to maintain safety compliance and the disasters have continued”.

In 2019, 67 people were killed when a complex housing warehouses, shops and apartments caught fire.

Responding to this latest tragedy the International Labor Association gave this statement:

“This incident illustrates the urgent need in Bangladesh for authorities and building owners to ensure that buildings in which thousands of workers spend the better part of their day are built and operated in compliance with national code requirements. If the fire safety measures required by the regulations were properly implemented, it would provide for the safe evacuation of occupants in this type of emergency”.

This cannot and should not ever happen again. Tighter regulations must ensure worker’s safety and we should never have to write another story like this.

When the people take back the power and hold public officials accountable, then and only then, will conditions change. In 1991, after the Imperial Chicken processing plant caught fire in Hamlet, North Carolina in which 25 people were killed, the owner did just under 4 years in prison because he had ordered the doors padlocked from the outside. It was not nearly enough, but it was the first time in North Carolina that someone did real prison time for safety violations.

This was a time of reckoning for NCs safety programmes. Laws were passed, people were held accountable. The feds threatened to take over North Carolina Labor unless certain minimum standards were implemented and John C. Brooks, Labor Commissioner at the time, lost the next election. Since 2004, North Carolina has been ranked in the top 5 safest states to work.

By Dr Bill Pomfret

- Published in Uncategorized

Now from Marcé – 4×4 CAFS Pumper

Engine: 326HP/240Kw EURO3 – 1250Nm Transmission: ZF 9S-1310

Marcé body cab with integrated crew cab and equipment lockers. The spacious crew cab provides seating for four crew members including gear and each seating position is equipped with a (BA) Breathing Apparatus seat allowing quick access and fitment of BAs.

The Unique design of the Marcé body or superstructure allows for six spacious lockers that can be easily reached by means of a drop-down step allowing the fire fighter to reach the required equipment. The equipment is safely stored inside the compartments by means of durable aluminium roller shutter doors each fitted with central locking controlled from within the vehicle cab.

The water and foam carrying capacity is 3000L and 300L.

The compact PTO driven multi pressure rear mounted fire pump has a maximum low pressure flow of 6000 litres per minute and maximum high pressure flow of 770 litres per minute. The maximum low pressure is 17 bar and maximum high pressure is 54.5 bar.

The pump is also fitted with two very unique foam systems namely a (CAFS) Compressed Air Foam system and electronic (ATP) Around The Pump foam system.

A Compressed Air Foam System simultaneously attacks all sides of the fire triangle.

• Penetrates and soaks the fuel

• Decreases the fuel’s exposure to oxygen

• Adheres to surfaces to reduce heat

Attacking a fire using CAFS reduces the amount of time to knockdown a fire by as much as 5 times over plain water. This equates to less fire fighter exposure, less water usage, less harmful runoff, and less required overhaul. There are multiple advantages for the front line fire fighter. CAFS helps keep them safer in the hostile environment of a fire scene and reduces attack times, reduces flashover, reduces hose line weight, and reduces exposure and fatigue.

The CAFS system ..balancing the water pump, foam system, and air system so they work effectively together. The CAFS procedure is simplified by fully programmable presets allowing the fire fighters to set CAFS configurations for numerous fire scenarios repeatedly with a single touch. The simplified operation allows changes to the CAFS consistency that is available at the push of a button. A twin-screw rotary air compressor delivers air flow volume of 200 SCFM (in metric terms – 5760 l/min) to match the pump.

The Smart ATP foam system is an intelligent, automated around-the-pump foam system that delivers high-volume, precise foam for every fire situation therefore eliminating the problems with traditional manual systems. The Smart ATP automatically regulates the foam ratio control valve, reducing the opportunity for operator error and wasted foam. Foam ratio percentage can be adjusted from 0.1% to 10% suitable for ARFF, Industrial, structural and Wildland Forestry fire fighting applications.

The vehicle is also equipped with an extremely durable deck monitor (water cannon) that is both wired and wireless providing improved performance and operator control. The maximum flow rate is 5000LPM. The monitor is programmable for STOW, DEPLOY and OSCILLATION, programmable travel limits and keep out zones as well as travel speeds. The monitor is mounted on a electrical actuated extender designed to provide better clearance for the monitor which allows for a wider coverage range and addresses firefighter safety concerns. The Extender deploys in 10 seconds and extends a full 457mm.

In addition to the two CAFS outlets, two water outlets and monitor outlet there is also two electric rewind hose reels capable of reaching pressures in excess of 45bar. Each hose reel is fitted with 45m long high pressure hose and an adjustable pistol grip firefighting nozzle.

- Published in Uncategorized